The syngas plant produces ultra clean gas, oil and char.

Almost all type of waste can be processed.

The gas is certified as substitute of natural gas with high content of hydrogen.

The char can be used as fertilizers or sold to the industrial industry and used as raw material.

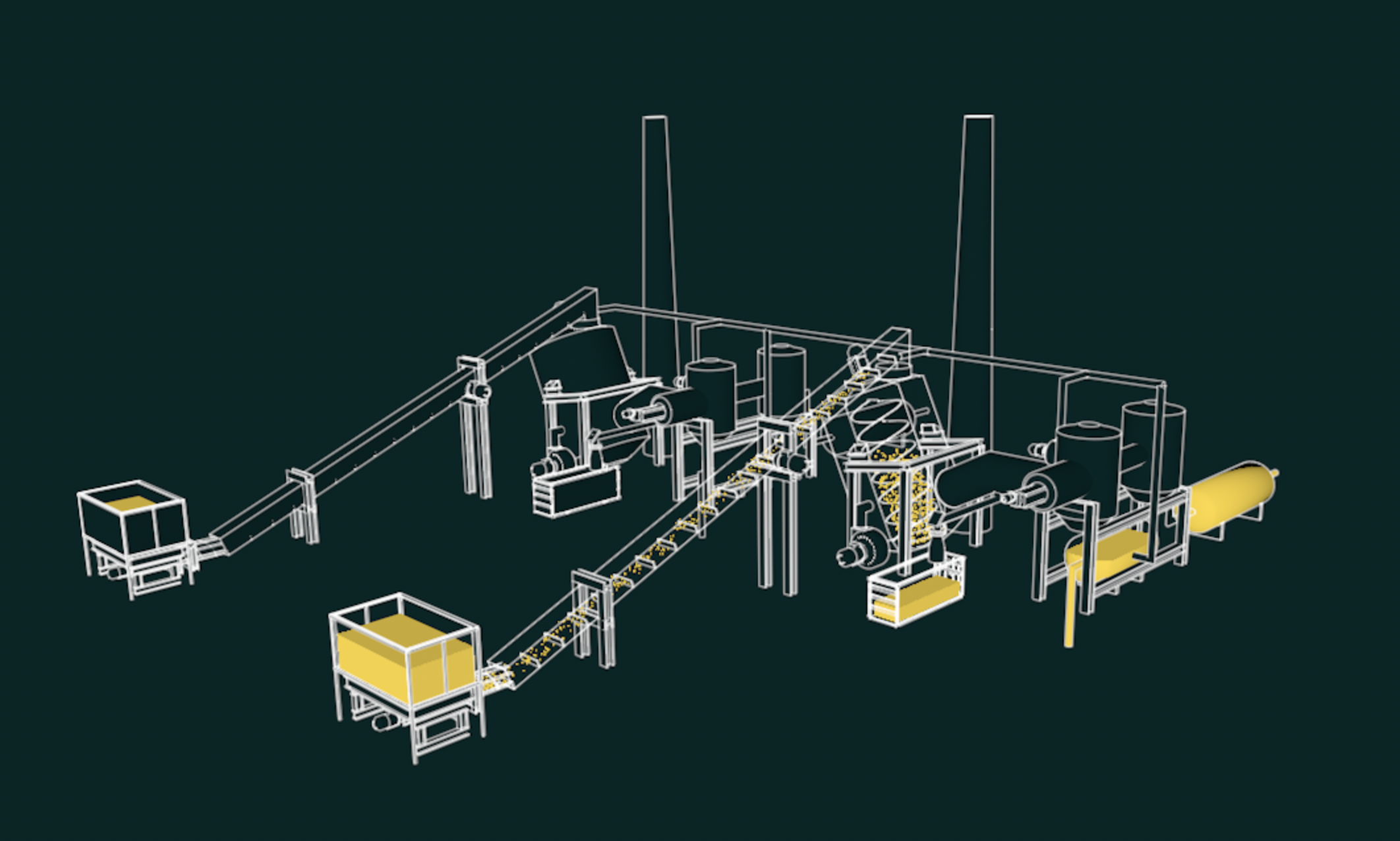

The modular design is standardized which make it easy to scale it. The plant is small in size with a much lower investment cost and operating costs than competing solutions.

Our Solution

The syngas plant produces syngas, which has a composition similar to natural gas and low contamination, light oil and coke. A key advantage of the syngas process is that no lean gas, but a high calorific syngas is produced.

Energy Produced

With feedstock waste a yield of about 320 cubic meters of gas and 80 kg of oil (energy approximately 3,000 kW) per ton feedstock is achieved.

A 50 000 tons per year plant generates apprx. 17MW/h, dependent on the feedstock type.

Modular Design

The design is build on a modular solution which makes it easy to scale it up to the required need of the customer or city (25 000t/a, 50 000t/a, 100 000t/a). No R&D is required to scale it to a higher demand.

Suitable for companies

The plant can be operated starting from 25 000 tons per year throughput with a space requirement of only 40 x 30m. Which makes is suitable for for both medium size companies and larger cities. This makes it a cost effective solution for companies that require high demand of energy, where they can use their own waste as feedstock. .

Suitable for cities

Due to the breakthrough technology the syn gas plant is developed to be unequivocally economical to install and manage at nearly any landfill site, creating sustainable electricity for the local communities. The syn gas can be applied to the local power grid.

Tested and Guaranteed

The syn gas plant has been tested and guaranteed for direct supply to the following gas generator manufacturing systems:

• Simens AG

• GE Jenbacher

• Bayer

• Deutch and MWV ( Caterpillar)

Conversion to Hydrogen

The syn gas produced is hydrogen rich which makes it easy to extract up to enrich and extract up to 99% hydrogen.